Let’s get it clear: What makes a good cushion? 7. Standard of evidence

In previous articles in this series, we have looked at elements of cushion design that influence a cushion’s properties for managing skin health and tissue integrity, for providing postural support, and for aspects of functionality. This article looks at some of the specific data that have been generated for a wide range of cushions, all of which establishes that no two cushions are the same, and that a cushion selected for a client needs to be selected around the specific characteristics which suit that individual client’s needs.

Are there any differences between one cushion and the next and, if so, how much difference is there? What do the values from cushion characteristic tests mean for the end user? These are valid questions, and are important when explaining to procurement departments that all cushions are not the same – even within the ‘same’ category (see below).

There’s a number of cushion characteristics which we can measure, and that are important for the well-being of the client. These include aspects such as pressure distribution, immersion, envelopment, stability, temperature regulation, moisture regulation, changes with aging, amongst others. This builds a complex picture of each cushion, and to help actually quantify these aspects there are a number of tests covered by a range of International standards within the ISO 16840 series.

Wheelchair and cushion information

The University of Pittsburgh’s Wheelchair & Cushion Standards Group is using an NIDILRR1 grant to translate these ISO performance standards into a way that is understandable and gives practical and applicable advice which can be used by healthcare professionals, manufacturers, wheelchair users, etc, to implement and call upon in daily practice. The results of their work to date can be found on their website.

This site is an excellent resource, with useful fact sheets on a variety of topics, for example, aspects of wheelchair performance, as well as on Cushion Performance Overview and a Cushion Performance Interpretation Guide. The latter covers seven of the available tests, explaining the reason why each is used, a summary of the test (with pictures of the test set-up), the range of values found across a range of cushions, and an indication of the significance of being at one end or the other of a range of values for that test.

If you turn to the ‘Explore Our Data Tab’, here you will find data for around 50 different cushions, measuring:

- Loaded Contour Depth and Overload Deflection (ISO 16840-22 Clause 11): a test to evaluate a cushion’s ability to immerse the buttocks

- Envelopment (ISO 16840-124): a test that characterizes a cushion’s ability to envelop and immerse the buttocks (data to be added shortly)

- Hysteresis (ISO 16840-22 Clause 14): a test to evaluate a cushion’s ability to provide support consistently during a cycle of loading and unloading

- Impact Damping (ISO 16840-22 Clause 9): a test to evaluate a cushion’s ability to reduce impact loading on tissues and help maintain postural stability when performing tasks such as going off a kerb

- Horizontal Stiffness (ISO 16840-22 Annex C): a test to evaluate a cushion’s response to slight horizontal movements in the forward direction

This report also shows the effects of accelerated aging (using methodology from ISO 16840-63) involving laundering, disinfection, accelerated aging, and cyclic loading protocols on some of the cushions for various of the previous measures, as well as

- Pressure Mapping (ISO 16840-63 Clause 14): a test that utilizes interface pressure measurements to assess the magnitude and distribution of pressure on a loaded cushion

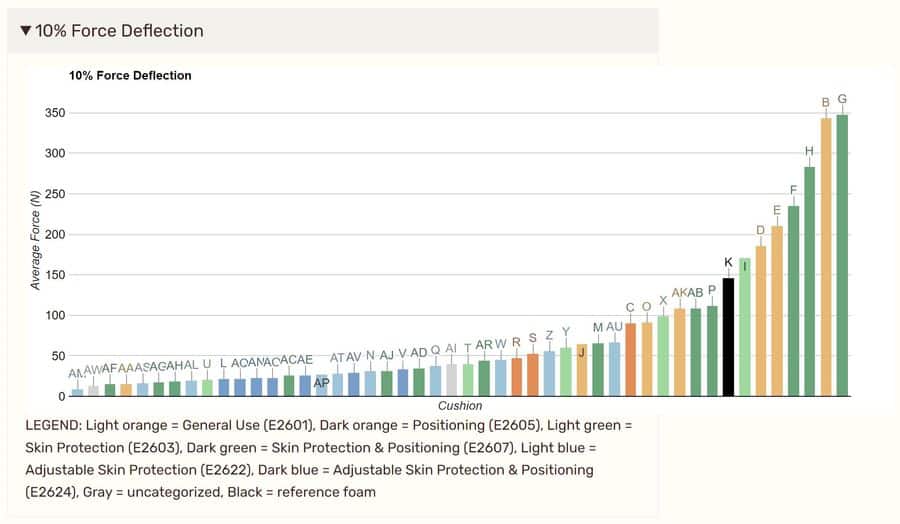

- 10% Force Deflection (ISO 16840-63 Clause 20): a test to evaluate a cushion’s ability to ‘cushion’ or elastically deform by measuring the force necessary to produce a deflection of 10% of the cushion thickness

The accelerated ageing protocols were then repeated a second time from which one can see which of the tested cushions saw their characteristics change the first time round, and which ones changed again after the repeated aging process.

Test data

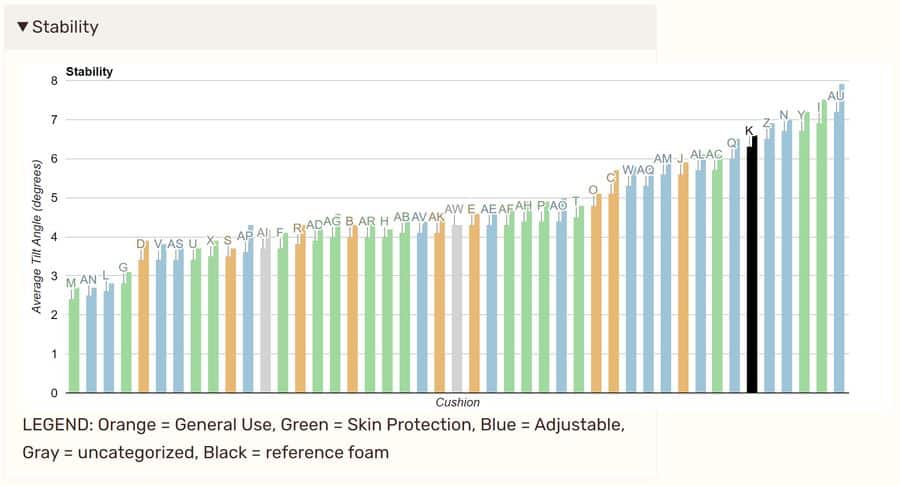

For all the tests, the values are provided for comparison purposes with those for a reference foam cushion made up of a 3” thick, high density polyurethane foam with a 25% IFD of 170 N and 65% IFD of 320 N. The reference foam cushion had a cover with a 2-way stretch nylon/spandex top and non-slip polyester bottom.

On this report, you can select tabs for the different tests which colour code the cushions by their ‘CMS code’. What is a CMS code I hear you ask – well, unlike the UK where we do not have codes, in the US, the Centers for Medicare and Medicaid Services (CMS) have created codes which cover certain criteria which a cushion has to meet for that code, and from that the reimbursement level it receives. The separate codes cover cushions for: General Use; Positioning; Skin Protection; Skin Protection and Positioning; Adjustable Skin Protection; and Adjustable Skin Protection and Positioning.

A couple of the graphs are reproduced here as Figures 1 and 2 showing the different performances of the cushions tested against the parameters of stability and force deflection. Note that cushions M and AU, for example, are at opposite extremes in Figure 1, whereas they have similar values in Figure 2. To apply the data in a helpful manner, one needs to choose a measure or measures that is/are appropriate for your client’s needs.

It is also interesting to note that generally the cushions do not group together by their CMS code: this raises the question as to whether the bases for these codes have been set alongside the most appropriate criteria. (The coding is based upon the Loaded Contour Depth test with added immersion and overload deflection requirements per code.) At least these criteria are somewhat better than defining a cushion by what it is made from, or what it looks like, which has occurred in some tendering processes in the UK.

At this stage, all the cushions have been ‘blinded’ while permission is sought from the manufacturers to identify their cushions, but why not ask your supplier which cushion letter represents their tested cushion? The important thing to note is that the data are not pass/fail criteria, and do not point to one cushion necessarily being ‘better’ than another. For some clients it is important for them to have a cushion performing at one end of a scale, while for others it might be the opposite end.

Eventually, the Pitt team aims to bring all the data together, to populate, in the Cushion Concierge page, cushion performance data resource, based on these ISO standard tests. This resource can then be used to help healthcare professionals transform the wheelchair cushion selection process, and advance evidence-based clinical practice.

References

- The National Institute on Disability, Independent Living, and Rehabilitation Research

- ISO 16840-2:2018 Determination of physical and mechanical characteristics of seat cushions intended to manage tissue integrity

- ISO 16840-6:2015 Simulated use and determination of the changes in properties of seat cushions

- ISO 16840-12:2021 Apparatus and method for cushion envelopment testing

Dr Barend ter Haar has been involved in seating and mobility for over 30 years, including lecturing internationally and developing international seating standards.

Click to read more from the ‘Let’s get it clear’ series from Dr Barend ter Haar